The 3.0 V6 diesel engine, called the OM642 was Mercedes’s replacement of the inline 5 and 6-cylinder diesel engines. The inline diesel engines were replaced by the OM642 unit because it offered the same power in a smaller V package and better environmental footprint.

I personally own this engine in my W211 Mercedes E-Class and have personally spent more than $3000 in just engine repairs. Most of the problems listed in this article are repairs I’ve done on my personal car.

Common Mercedes OM642 engine problems include:

- Oil cooler o-ring leaks

- PCV valve problems

- Leaky piezo fuel injectors causing oil dilution

- “Black Death” around fuel injectors

- Turbo inlet pipe leak

- TWC Temperature sensor issues

- Turbo actuator problems (due to oil contamination)

- Swirl flap motor problems

- Carbon deposits

- Oil diulution

Many people were disappointed by the decision, as the inline 5 and 6 engines, the 270 CDI and 320 CDI were considered to be the pinnacle of Mercedes diesel engineering.

However, the OM642 proved to be an amazing and reliable engine. They do however have a few annoying engine problems that occur after 100,000 miles (ca. 160,934 km) and 10 years. It also heavily depends on the maintenance the engine receives and how it is driven.

Which Mercedes-Benz cars have the OM642 diesel engine?

You can find this engine fitted to many Mercedes-Benz cars and vans. Here is a complete list from Wikipedia.

- Mercedes-Benz S 320/350 CDI/BlueTEC (2005–2013)

- Mercedes-Benz GL350 BlueTEC/GLS 350d (2012–2018)

- Mercedes-Benz ML350 BlueTEC/GLE 350d (2011–2018)

- Mercedes-Benz GLC 350d (2016–2019)

- Mercedes-Benz E350 CDI/BlueTEC (2010–2016)

- Mercedes-Benz E280/E300/E320 CDI/BlueTEC (2007–2009)

- Mercedes-Benz G320 CDI/G350 CDI/BlueTEC (2007–2018)

- Mercedes-Benz C320 CDI (2005–2007)

- Mercedes-Benz C320/C 350 CDI (2009–2014)

- Mercedes-Benz GLK 350 CDI (2013–2015)

- Mercedes-Benz CLS 320/350 CDI (2005–2011)

- Jeep Commander XK/XH (2006-2010 (Europe))

- Mercedes-Benz GL 320/350 CDI/BlueTEC (2006–2012)

- Jeep Grand Cherokee WK/WH (2005-2010 (Europe)1, 2007-2008 (North America)2)

- Mercedes-Benz R320/R350 CDI/BlueTEC (2007–2012)

- Mercedes-Benz E 350d (2016–2018)

- Chrysler 300C (2006–2011) (Europe, Australia and New Zealand only)

- Mercedes-Benz ML 280/ML 300/ML 320/ML350 CDI/BlueTEC (2007–2011)

- Mercedes-Benz S350 BlueTEC/S 350d (2013–2017)

- Mercedes-Benz CLK 320 CDI (2005–2010)

- Dodge / Freightliner Trucks / Mercedes-Benz Sprinter (2006–Present)

Mercedes OM642 Oil cooler leak

Let’s start with the most common Mercedes OM642 engine problem which is the oil leak that occurs at the oil cooler. This does not sound like a big deal, it is supposedly just a small oil leak, but the problem is not the leak, it is the location of the leak.

Imagine the V6 engine as what it is, a V letter that has a big valley at the bottom of that V. At the bottom lies the infamous oil cooler that has 2 round seals. That is where the leak occurs, at the bottom of the V at those 2 round seals.

This is a costly repair and if it wasn’t done before, you’ll most likely be the one doing it. I had this repair taken care of in the first week of my ownership.

The problem is that you cannot reach those 2 seals from the bottom, a mechanic must dismount everything that lies in the way from the oil cooler. And that is a lot of work, we are talking 5-6 hours of expensive labor. The seals themselves cost nothing compared to the cost of labor, they cost around 30$.

Oil Cooler Leak Symptoms

From what we have read and heard, most people start experiencing these oil cooler leak problems after 100,000 miles or 10 years. The main symptom of the OM642 oil cooler leak is the disappearing oil from the engine and an oil stain on your driveway or garage floor. Eventually, the leak will become so big, you will have no other option but to take care of it.

Mercedes replaced the faulty oil cooler seals (orange coloured) with new seals, made from a better Viton material (violet colored). So hopefully, you will only need to deal with this issue once in the lifespan of the engine.

This problem was only present on OM642 engines built before 2010, newer engines received the updated Viton version of the oil cooler seals.

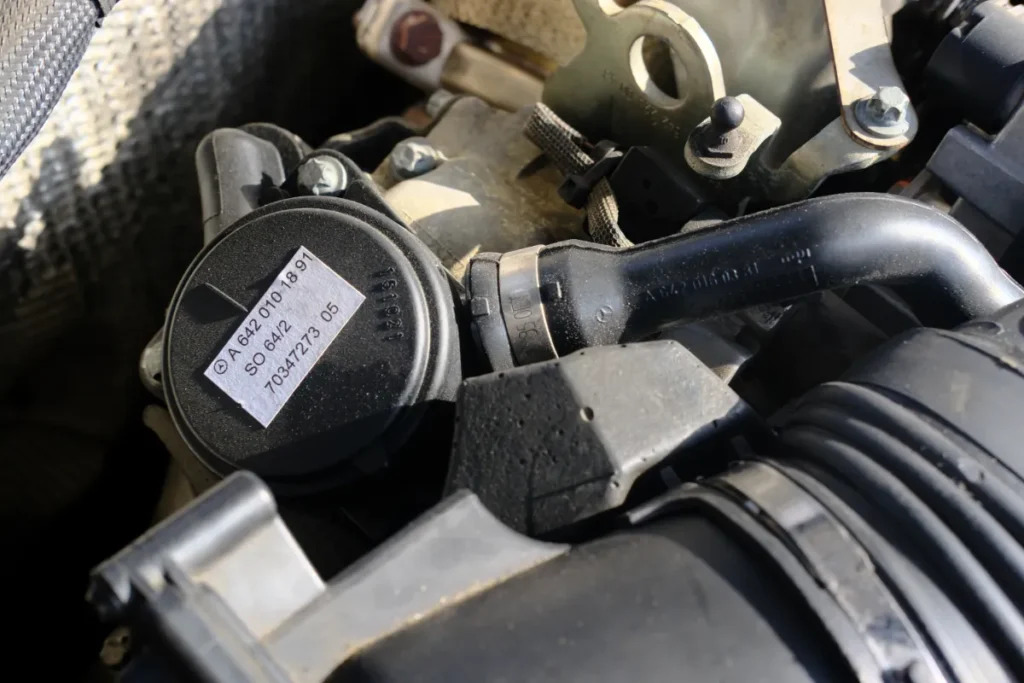

Positive Crankcase Ventilation (PCV) Problems

The positive crankcase ventilation on the OM642 engine is routed to the inlet of the Garrett turbocharger. Overtime, if the ventilated air contains too many oily vapors, the swirl motor valves that let that air through can become contaminated to the point where the swirl motor valves become too dirty to operate normally.

As this happens, the swirl flap motor blows a fuse to protect the engine. This fuse is also responsible for several other sensors that make the engine run, so when it blows, the car goes into limp mode.

This can happen without previous symptoms so as the car ages, we advise you to get the intake system and the PCV system checked out for carbon and oil sludge deposits.

Cleaning the entire system will prevent further potential damage. We advise you to clean the air intake manifolds, intake pipes and the crankcase ventilation pipes every 70,000 miles.

This problem is especially common on vehicles that are often driven in the city or for short distances in general.

“Black Death” Fuel Injector Problem

One of the common Mercedes OM642 engine problems is the so called “black death”. If you spent some time in Mercedes-Benz diesel forums, you have surely heard of the infamous “black death” fuel injector problem.

This is only a big problem if it remains undiagnosed or ignored. We have written an extensive article on fuel injector problems, we recommend you read it.

The problem does not lie in the injectors themselves, the problematic part are the copper washers around the injector. The copper washers are poorly designed which leads to leaks of uncombusted diesel fuel and exhaust gasses past the copper washers.

The uncombusted fuel and exhaust gasses then deposit around the copper washer and the fuel injector. This leaves a big mess and the fuel injectors themselves become lodged (really, really stuck in there) in the engine.

Eventually the fuel injectors are doomed to fail which results in a big cloud of smoke behind the car and a loss of power. Replacing the failed injector is difficult because there is usually a lot of heavy residue to clean around the injectors and the injectors get burnt into the engine.

Mercedes OM642 Turbo Inlet Seal Leak

The turbocharger inlet seals (big read seals) are known to leak in these engines as they operate under massive amounts of pressure. A leaking seal can cause a lot of trouble in the engine as the oil drips from the turbo inlet, down through the V engine “valley”.

One thing that gets damaged with bad turbocharger inlet seals is the swirl motor which is a crucial part of the engine. The swirl motor is located right beneath the turbo inlet and any oil drips can cause it to fail.

Many owners report leaks even after changing the seals which leads us to believe that the entire system is just poorly designed. I solved this issue by replacing the entire Y inlet pipe with the seal.

My red seal was intact, however, the inlet plastic pipe was cracked due to age or poor handling from the previous owner, which means there was not enough pressure on the seal itself.

A full new inlet pipe comes with 2 integrated mass flow sensors which means its not cheap, you’re lucky if you get an OEM replacement part for $300.

Due to the price of a new inlet pipe, some owners install oil catch pans beneath the turbo inlet to prevent drippage to the swirl flap motor. Other owners tend to buy aftermarket inlet pipes of questionable quality or they do other forms of DIY repairs with aftermarket inlet gasket seals.

Timing Chain and Tensioner Problems

The OM642 V6 diesel engine likes to be driven easily when it is cold. All engines should be treated like this, but especially the OM642 V6 diesel engines.

The timing chain and tensioner usually need to be replaced at the 150,000-mile mark but we commonly see timing chains being replaced much sooner. And many of those cars are driven without a care, even when cold.

It is common that a faulty chain tensioner is at fault for the timing chain rattle, replacing the tensioners will relieve the annoying rattle sound but eventually the chain will need to be replaced as well.

The symptoms of worn timing chain tensioners are often overlooked which leads to timing chain damage. The key here is to always be on the lookout for any kind of metal rattling when you turn on the engine (a typical symptom is a 2 second rattle right at the ignition”).

Your mechanic should notice it immediately when you take it in for a normal service. To avoid this issue read our guide on how to drive and maintain a diesel car.

OM642 TWC Temperature Sensor Issues

On early OM642 models, the TWC temperature sensor was prone to failure, but the issue was resolved by Mercedes releasing a new part. Failed temperature sensors caused the check engine light to illuminate on the dashboard.

Most vehicles, used and new with the OM642 engine should have this problem taken care of already, so no worries here.

Turbo Actuator Problems and Symptoms

While not a common OM642 problem, the turbo actuator that is responsible for the turbocharger to kick in is known to cause issues on particular occasions.

A replacement pair is extremely expensive which is why many people choose to repair the actuator at specialized car electric shops or at home.

Typical symptoms include a late turbocharger activation, poor acceleration, very little power at higher speeds, jittering of the turbo. There are several forum threads with owners describing this issue, but the most helpful one is this one here.

Swirl Flap Motor Problems and Deletion

Swirl flaps are located in the intake manifold and their main job is to improve the fuel-air mix at low speeds. The swirl flap motor’s job is to open and close these plastic flaps when needed.

If it fails the engine goes into an immediate limp mode as it cannot open the swirl flaps when needed. The engine goes into limp mode to protect itself as you do not wish to detach one of the swirl flaps and get it inside your engine where it can cause serious damage.

The cost of repairs is not small so many owners opt in for the complete swirl flap motor and flaps deletion. Without the swirl flap motor and flaps, the car runs just as good, without a difference really. The only thing you can notice is a bit more smoke when you accelerate.

One common reason for the swirl flap motor malfunction is the oil that leaks from the turbocharger inlet seal above the motor. The oil gets inside the motor and causes a malfunction.

Inlet Manifold Carbon Deposits

The intake manifolds of all diesel engines are prone to get dirty with carbon buildup and soot (the OM612 diesel engine included). The intake manifold is responsible for delivering the correct amount of air into the air chamber of the cylinder. If it gets dirty with carbon deposits and soot, you can expect the engine to stall, misfire, idle roughly, lose power etc.

Dirty intake manifold and swirl flaps are a menace to the engine and you should have them cleaned as soon as possible.

Detached particles of carbon and soot can get sucked into the engine and cause problems. If the swirl flaps themselves are dirty, they can get stuck.

There are a number of problems that can arise by having dirt built up in the intake manifold so it is important to have the engine inspected and cleaned if needed. Diesel cars that make plenty of short trips and do a lot of stop-and-go city driving are more prone to carbon buildup in the engine.

OM642 Engine Oil Level Rising (Fuel Dilution)

We recently wrote an article on another common issue with the OM642 engine which is the rising oil level that comes as a consequence of fuel dilution. Read my experience with rising oil levels on my OM642 W211 320CDI and learn more about why fuel dilution happens.

Conclusion

The OM642 is generally considered to be very reliable for a V6 diesel engine. Especially when you compare it to some other diesel engines in premium cars. The one thing that makes the OM642 engine act up is a lack of maintenance.

If you want to learn more about Mercedes engine problems, consult our guide to all the common Mercedes engine problems.

Buying a used Mercedes-Benz with an OM642 engine that was not properly maintained can quickly turn into a nightmare. Other than that, there are plenty of people covering insane mileages with these engines without ever speaking a bad word about it.

If you don’t want to take care of 6 cylinder, I would suggest choosing a 4 cylinder diesel like the OM646 engine.